Precision Tooling & Gaging Services

We build precision high-end tooling, gauges, and automated assemblies and specialize in grinding and EDM.

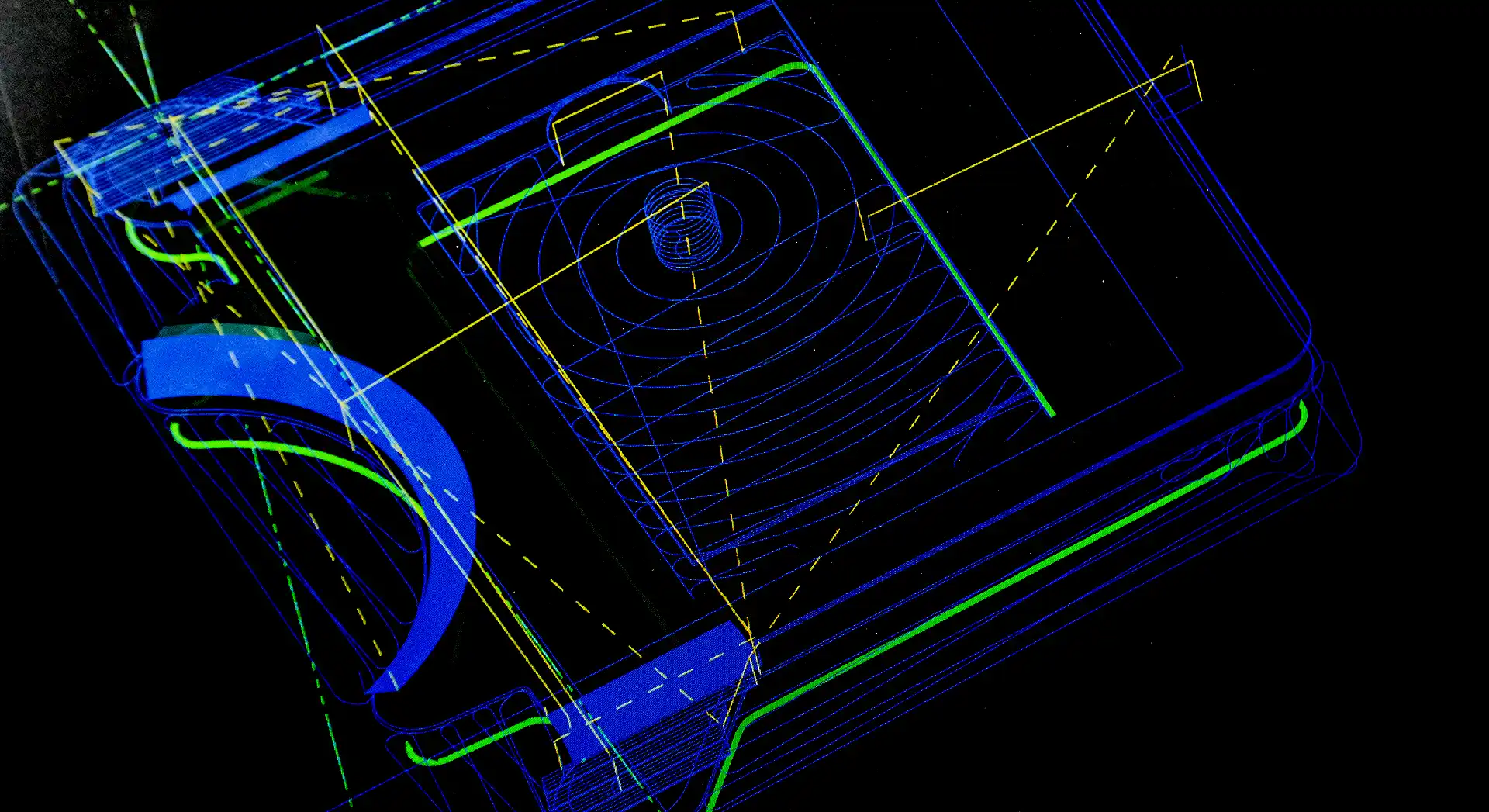

Engineering

Progressive Tool & Mfg offer a wide range of Engineering services. We use the latest AutoCad & Inventor software to make solid models and working drawings of all customer one-of-a-kind parts. We can then take those solid models and drawings directly into our CAM programing system to wrap toolpaths around your part for machining. Ryan got his degree in mechanical engineering from NCSU then served a formal 4 year apprenticeship, completed in 2012. With the perfect mixture of academic knowledge and 12 years shop experience, we have the ability to design and tolerance tooling that is not only practical but also cost effective.

Custom assembly fixtures, CMM fixtures, or shop floor jigs are every day things for us. Prototyping with rapid product iteration is well within our capabilities. We’ve worked with engineers on how to better their process and product during our history. We excel in fast turnaround and rapid prototyping.

Wear Item/Replacement Tooling

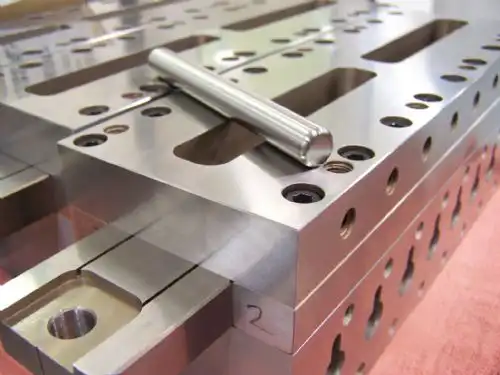

Progressive Tool stands ready to support manufacturers with wear item and replacement tooling needs, offering innovative solutions to minimize downtime and maximize efficiency. Are you tired of the hassle of ordering wear items months in advance, only to find yourself stranded when they break unexpectedly? PTM has the solution! With ample storage space, PTM is able to make and store custom machining fixtures for your wear item to facilitate the quickest turn around. Do you have custom punch and die systems that require frequent sharpening, disrupting your production schedule? We offer resurfacing and regrinding services to extend the lifespan of your existing tooling, saving you time and money on replacements. We regularly grind surfaces flat within .0001” with a Ra 2 surface finish. Do you have a custom punch and die system that needs sharpening? PTM has you covered. Our typical turnaround for resharpening is 1-2 weeks.

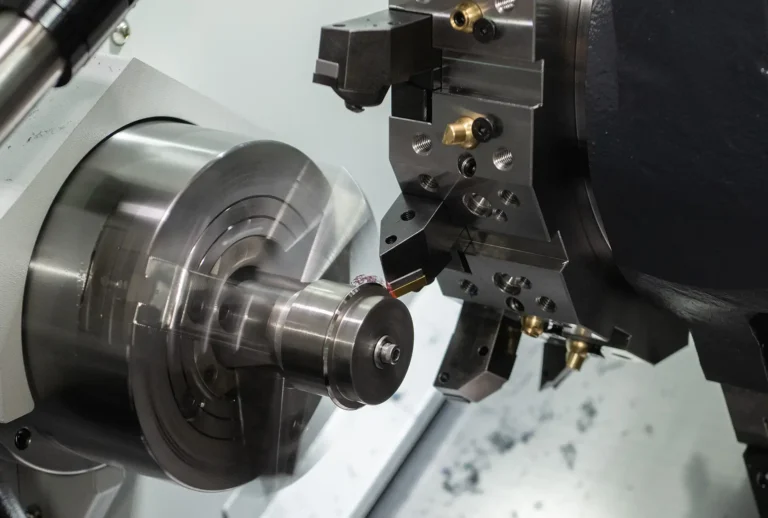

Hard Processing

Progressive Tool excels in providing solutions for hard processing, embracing the challenges of working with hardened materials that require grinding and EDM finishing. With about one-third of our floor space dedicated to finishing operations like grinding and EDM, we’re fully equipped to handle even the toughest projects. Tight tolerance hardened tooling is what we do best! Our facility boasts a range of advanced machinery, including a universal cylindrical grinder, a centerless grinder, and surface grinders enabling us to tackle the most demanding tasks with ease. From intricate components for molds to custom tooling for manufacturing processes, our skilled toolmakers love taking on the tough stuff, leveraging these resources to deliver exceptional results. At Progressive Tool, we thrive on pushing the limits of our machines and exceeding expectations. If you have tooling that MUST fit your existing setups the first time, every time, Progressive Tool is the clear choice. With Progressive Tool as your partner, you can trust that your hard processing needs will be met with efficiency, precision, and a passion for tackling challenges head-on.

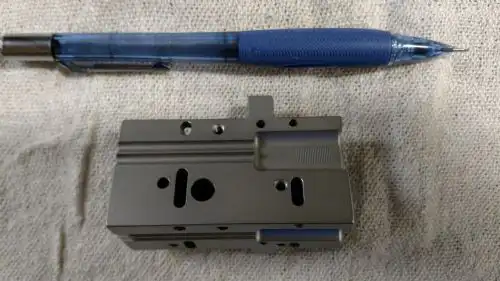

Precision Tooling

Precision one of a kind custom tooling is our bread and butter. Our typical quantities run from 1 to 50. The ability to integrate with our customers and help solve specific problems has gained us their trust, respect, and confidence. We routinely work with manufacturing, process and tooling engineers, designers and quality control personnel to make sure the end result will satisfy their specific needs.

Becoming involved with a customer’s processes and products is one of the most valuable services we offer. Our expertise can make your tooling and manufacturing process more efficient, longer lasting, work better and be more cost effective. From intricate molds and dies to complex fixtures and components, our expertise spans a wide range of precision tooling needs. Whether you require tight-tolerance machining, intricate surface finishing, or custom tool design, Progressive Tool has the capability and experience to bring your vision to life.

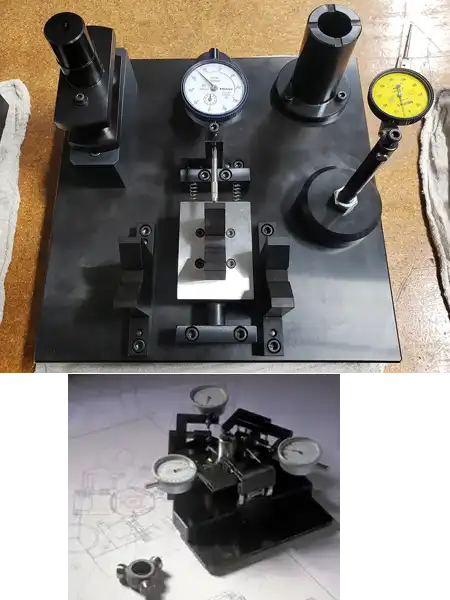

Custom Gages

Progressive Tool offers in-house design capabilities to design and manufacture custom one-of-a-kind gages for your parts. Utilizing our expertise in mechanical engineering and shop floor experience, we craft custom gauges that are not only cost-effective but also easy to use, taking the human error out of the equation. With our in-house design capabilities using Autodesk Inventor, we ensure that every aspect of our measuring systems is meticulously engineered for reliability and precision. By providing solid models and working drawings with appropriate dimensions and tolerances, we guarantee seamless integration into your processes.

We design intuitive measuring systems that are easy to operate and minimize the risk of inaccuracies caused by operator influence. This ensures consistent and reliable measurements, enhancing the quality control process. Partner with Progressive Tool for custom gauge solutions that streamline your operations, improve quality control, and drive efficiency. Contact us today to discuss your specific requirements and discover how our custom measuring systems can enhance your processes.

OEM Replacement / Reverse Engineering

Progressive Tool leads the industry in OEM replacement and reverse engineering services, delivering precision solutions exceeding OEM specifications. Leveraging our mechanical engineering expertise and shop floor experience, we specialize in crafting custom replacements for a range of parts, including brackets, sprockets, custom gears, and modifications to OEM components. Using advanced software like Autodesk Inventor, our in-house design capabilities ensure meticulous reverse engineering, guaranteeing accuracy and compatibility. We provide comprehensive support, assisting with material selection, proper tolerancing, and reverse engineering from broken parts, even if the customer lacks documentation.

Beyond replication, we optimize designs for enhanced performance, durability, and efficiency while adhering to OEM standards. Our replacements often surpass original components in quality and longevity. At Progressive Tool, we prioritize minimizing downtime and maximizing productivity. With fast turnaround times and tailored solutions, whether for one-off replacements or ongoing production, we’re dedicated to exceeding expectations. Choose Progressive Tool for OEM replacement and reverse engineering services that elevate your operations. Contact us to discuss your needs and experience precision and reliability unmatched in the industry.