History of Progressive Tool

Our story begins in 1984 with two brothers...

1984

In 1984, two brothers, Daniel and Richard Thompson decided to go into business together and start their own Tool and Die shop. Originally from Rochester, NY they moved to Greensboro, NC to be in an area that was growing and would need the kind of tooling they were capable of making. Each of them had completed a formal 4 year apprenticeship in tool and die making in Rochester and had years of experience in the trade. Starting their own business in the basement at one of their homes, they quickly outgrew their humble beginnings.

1985

In 1985 they moved into a 5,000 square foot building, hired their first apprentice (who recently retired after many years of service), and continued a steady growth. Progressive Tool gained a reputation for building top notch precision tooling. At that time they had traditional metalworking equipment including manual and CNC mills, lathes, and surface grinders. They added cylindrical grinding and sinker EDM and within a few years were at 5 employees.

1990

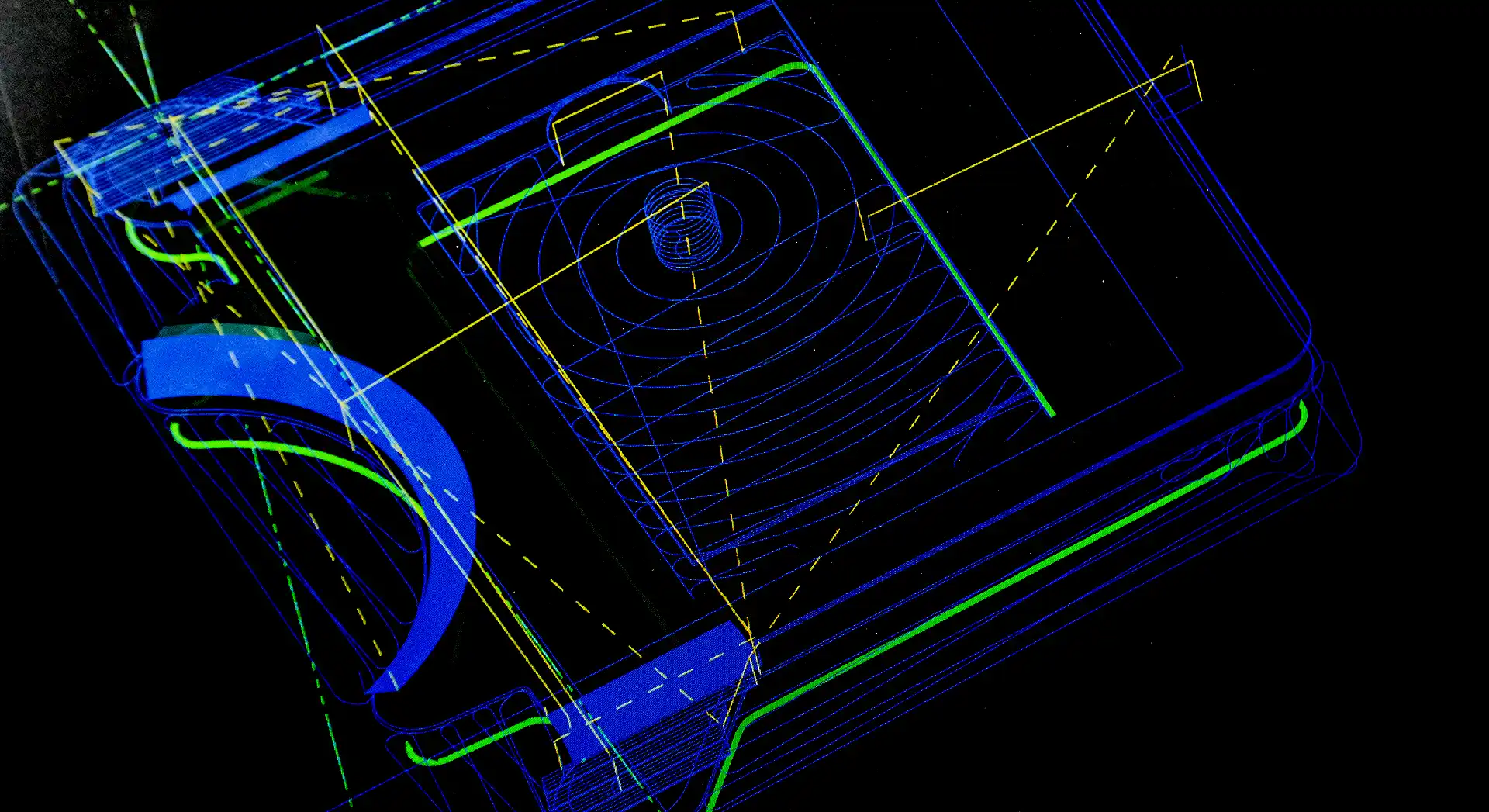

In 1990 they bought their first wire EDM, a new Mitsubishi 90C, which they had seen demonstrated at the 1990 International Machine Tool Show in Chicago. It was a huge expense for a small growing company, but they could see the need for this type equipment and were one of the first in the area to embrace the new technology. In 1991 they developed a line of modular gages that they have continually improved and added capabilities to, and still sell and support. EDM and getting involved with customer’s processes helped them continue to grow and by 1996 with 8 employees, they had outgrown their location.

1996

They built a 12,000 square foot brick building in the summer of 1996 and moved in between Christmas and New Years. They bought additional CNC equipment, and continued to grow adding a second wire EDM, and a high speed EDM drill. An inspection room was part of the new building, as well as conference rooms, administrative offices and design facilities. The next few years saw another big increase in technology. CAD and CAM were invested in. AutoCAD was purchased for design and Mastercam for programming as well as a DNC system for distributing part programs. Eventually a small business server was installed to tie everything together.

2005

In 2005 a 3,000 square foot addition was added to the shop for further expansion. Second generation wire EDM machines were purchased to replace the original ones. Larger turning centers with more capabilities and a larger machining center were also added. 3D solid modeling using AutoCAD Inventor was purchased and installed. Business continued to grow until the 2009 recession. A strong reputation helped weather the downturn in business and Progressive Tool rebounded in 2010 and is again in a healthy, growing, profitable state.

2017

In 2017 we made some updates to our now 20 year old building. Landscaping, replacing shrubs, re seeding on the outside, and replacing metal halite and conventional florescent lighting with LED in the entire building inside. The improvement in lighting is amazing, we have done away with some of the task lighting at individual machines and the overall improvement is above expectation. Also, quite a savings on my monthly light bill. We updated Mastercam to the 2017 version as well as replaced our workstations to accommodate the new software.

With the purchase of anew Doosan Lynx 220 LSYC lathe with a sub spindle, Y axis, live tooling, and parts conveyor, we are now able to finish parts in one work holding that previously needed multiple setups on multiple machines and fixtures. We routinely turn and mill the front side of a part, grab it with the sub spindle while still holding onto it with the main spindle, cut it off with a parting tool, then move the sub spindle to the back side of the turret and continue turning and milling the back side finished. Programming and tool holding get complex, but a good CAD CAM system helps us streamline operations.

A second generation Thompson is replacing his uncle Dan who retired recently. Ryan got his mechanical engineering degree from NC State then served a formal 4 year apprenticeship completed in 2012, and has continued in the shop as a toolmaker as well as doing our design work. Having a toolmaker design things that he knows how to build is a tremendous asset. Things are tolerance correctly and from the datum they should be, material selection and part configuration are done correctly so they can be made cost effectively. We are routinely designing or helping our customers design tooling that can be made efficiently.

What’s next for Progressive Tool?

We continue to look at new technology: More multi axis machining, combination mill and turn centers, 3-D printing, water jet, laser, robotics are all things being considered. With the exceptional talent of our employees and their unending eagerness to learn, anything is possible.

Come visit us to see what’s new in the always changing field of precision tool making.

We’re not your everyday machine shop!

Contact us to learn more. 336-664-1130