About Us

Serving precision tooling and gauging needs in central North Carolina since 1984.

Progressive Tool has been serving precision tooling and gauging needs in central North Carolina since 1984. We actively support apprenticeship training in tool and die making. All of our shop employees have either finished a four year apprenticeship or are now serving on one.

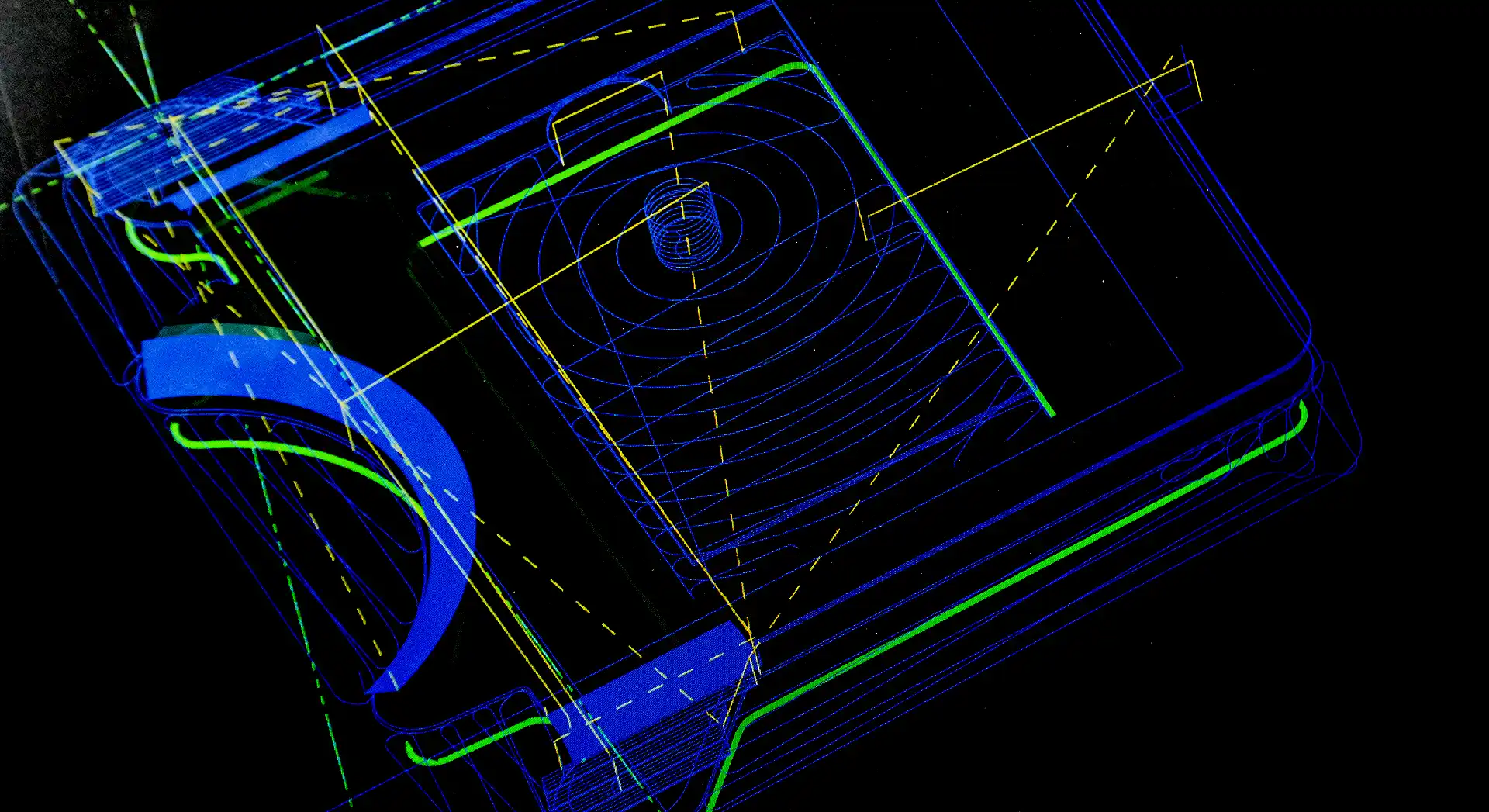

Using our experience to do the job right and efficiently from the start, helps builds quality into our tooling. Building precision tooling, gauges, and automated assemblies is what we are in business for, not a sideline. EDM work and grinding take up about 30% of our total shop floor space.

Our expertise can make your tooling or manufacturing process more efficient, longer lasting, work better and be more cost effective.

We have a reputation built on the four cornerstones of our business:

- Quality

- Service

- Problem-solving

- Developing strong working relationships with our customers.

Progressive Tool offers in-house design capabilities and can supply documents, assembly prints, and bills of materials.

We specialize in precision tooling that includes:

- Fixture gages and test equipment

- Alteration of tools and documentation of tooling changes

- Building of automated & specialty machinery

- One-off parts

- Building and maintenance of stamping dies

- Prototypes, R&D, and Test Equipment

- Dies, Die Alterations, Die Repair, Die Maintenance

Our work involves carbide and all grades of tool steel, which usually requires precision grinding (jig, surface, form, and cylindrical) or EDM (wire or CNC sinker) work. If you have an interest in or need for our services, call us at 336-664-1130 or contact us using the form below.

Progressive Tool strives to build new partnerships, working to help solve your problems and meet your tooling needs:

- Milling, Turning, Threading

- Tool modifications, custom tooling

- Metering pumps, Medicine pumps, Medical equipment

- Assembly equipment, automated assemblies

- Machine Building, Custom Machinery

- Specialty Tooling, Custom Manufacturing

- Precision Assemblies, Manufacturing Equipment

- Fixtures, Fixture Making

- CNC Turning, CNC Milling

We serve the Greensboro area at about a 100 mile radius. Check out our service areas and contact us to see if we can help you!